COVID-19 Impacts on Productivity Levels

Have you experienced reduced productivity levels due to COVID-19?

Our customers have and were surprised to find a solution that increased productivity beyond pre-COVID levels!

A common problem raised by our clients as a result of social distancing measures and the need to limit close human interaction is reduced productivity!

The challenge:

Social distancing makes it difficult to get two or more people interacting and working closely on assembly tasks, consequently the tasks take longer to complete. The level of impact: An increase of 30%+ in time required to complete an assembly stage.

The solution:

Partnering humans with made smarter Collaborative robots (integrated smart vision) capable of executing a range of assembly tasks to high levels of accuracy.

The “Surprise” Benefit:

Clients were surprised to find that collaborative teams of humans and Cobots resulted in a productivity increase beyond the levels achieved prior to Covid restrictions.

“Not using Cobots will be akin to a gardener not using a wheelbarrow!”

There is no doubt regarding the importance Cobots will play in maintaining competitive operations. In the future not using Cobots will be akin to a gardener not using a wheelbarrow! Garry Lofthouse, CEO at Applied integration states “the results we achieve correlate with a report produced by MIT that concludes a human working in collaboration with a Cobot is up to 85% more productive than either working alone!”

Top challenges faced by Industries contacting the Applied Integration team that can often be addressed by Robotics and Automation:

Covid19 social distancing rules restricting productivity

Struggling to recruit required personnel/ labour shortage

Difficult to meet customer response times/short lead times

Process cost making it difficult to remain competitive

Struggling to manage custom product/short batch runs)

Struggling to manage varying demand/on off shift patterns/overtime

Need for improved and repeatable quality

Can Cobots do this?

As standard Cobots (and industrial robots) can execute a wide range of repetitive tasks such as:

Assembly, component placing, nut running, screwing

Pick and place, sorting, packing

Welding, gluing, riveting

Polishing, sanding

Dispensing, inspection and test

Lifting

However, when integrated with industrial computation platforms, appropriate smart vision, and programmed intelligence the potential for execution of more complex, widely varying, and high precision/accuracy tasks becomes a reality.

If you are faced with process challenges feel free to contact us for a chat…. You will be surprised by what can be achieved.

Robot or Cobot?

An interesting question. Collaborative robots have the distinct advantage of working closely and safely with humans. In many applications they can operate without any guards and can be deployed on vast array of applications. Many of which are untapped!

As an integrator we are often faced with a preference for a Cobot as “they seem easy to install/use, safer and less expensive”. For many applications this is true, but collision detection, force and speed monitoring only get you so far, it is still a frequent occurrence where we find Industrial Robots are the ideal solution due to reach, payload, duty cycles and down force capabilities. As for safety, risks should be assessed on a case-by-case basis. For example, a Cobot welding, riveting application should still be appropriately guarded to ensure personal safety.

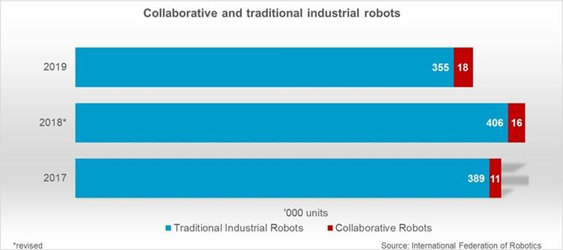

Cobot adoption by Industry:

The graph below reported by the IFR shows that Collaborative robots are still in their infancy but are growing rapidly with installations growing by 11% in 2019 resulting in a 4.8% market share of 373,000 robot installation. It is clear that this growth will continue to rise steeply in the next five years.

Applied Integration is a leading systems integrator, specialising in delivering the latest industry technologies with a focus on Industry 4.0, Digitalisation, Internet of Things (IoT), Analytics, Big data / Cloud Technologies, Safety Critical Systems (SIL1, SIL2, SIL3) and Robotics and Collaborative Robots (Cobots). Founded in 2005, AI has a dynamic, 50+ strong engineering team with many years combined experience.

Learn more www.appliedintegration.co.uk