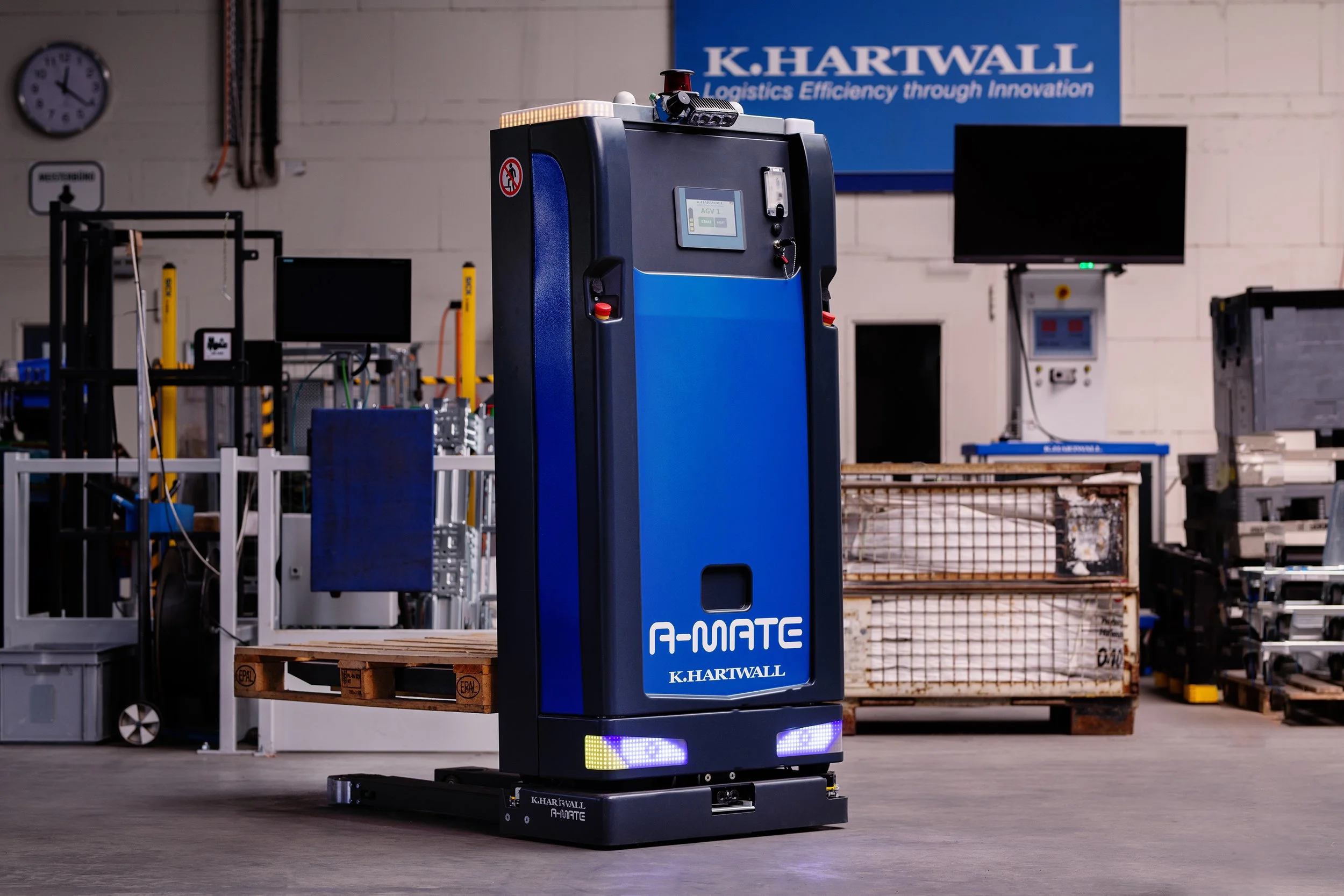

K.Hartwall

K.Hartwall’s A-MATE AMRs are designed to offer you a new way to reduce costs and increase efficiency in your logistics processes. AMRs allow you to decrease your dependence on skilled labor, process errors and the risk of accidents.

A-MATE mobile robots replace heavy and inefficient manual routines. Today, almost half of all working hours are spent on manual routine jobs. The World Economic Forum estimates that by 2035, automation will reduce that number to 35%. Key to this evolution is the increasing deployment of AGVs and autonomous mobile robots (AMRs), which, in addition to boosting efficiency, can literally take the load off their human coworkers’ backs.

Reduce damage and improve process visibility

Whereas manually-driven forklifts regularly hit load carriers and the products within them, A-MATE AMRs use the latest scanner technology and navigation software, making them extremely accurate.

Each of their tasks automatically leaves a trace, which enables you to track past incidents and better plan future operations.

A-MATE Counter

The counterbalanced AMR helps site managers with the transition to a partial or fully automated operation, ultimately paving the way for Industry 4.0. A-MATE® takes away repetitive tasks, freeing up the capacities of existing employees so they can perform more demanding tasks and ensures an autonomous and reliable performance 24/7. This reduces handing costs and improves efficiency of internal logistics.

The turning radius of 2800 mm combined with the bidirectional drive allows agile movement and turning, even in tight spaces. With a powerful electric free lift, the A-MATE® can pick up and drop off a maximum load of 1000 kg either from the floor or from shelves and conveyors up to a height of one meter. The A-MATE’s® cantilevered forks and counterweight enables pick up of closed pallets and euro containers.

A-MATE Freelift

With the unique design of the A-MATE you can achieve reduced dependence on labour and improvement on both the safety and efficiency of your operations.

This new generation omnidirectional mobile robot has 360 degree safety scanners at different heights and emergency stop buttons meaning it can safely work alongside humans. The best part is that it can be used to transport traditional load carrier solutions such as roll containers, lean adaptor pallets and dollies or foldable cages already in use in warehouses or plants.

The A-MATE has an exceptional runtime on a single battery charge and free lifting capability to handle loads of 1000 kg (1 tonne) up to a height of 1 meter. It can also pick loads to and from conveyor belts and transport them safely alongside other traffic to off-loading positions.